Molds / Tooling

A plastic injection mold, also known as mold tooling, is used in the production of plastic parts. The principle of plastic injection: heated plastic material is injected into a mold, then the cavity gives the part the desired shape.

To choose the type of plastic injection tooling best suited to your project, Unimold advise you according to your technical specifications, desired finish and the number of parts to be produced.

The various types of plastic injection

tooling according to quantitative requirements

Prototype mold

A prototype mold is used to make injection part prototypes. These parts are then used by the design office or marketing department to validate a visual or functional concept. This type of tooling enables limiting investments and maximising time savings.

Our solution: Unimold implemented a solution for this type of requirement with changeable mold base. Investment is therefore limited to the minimum number of cavities.

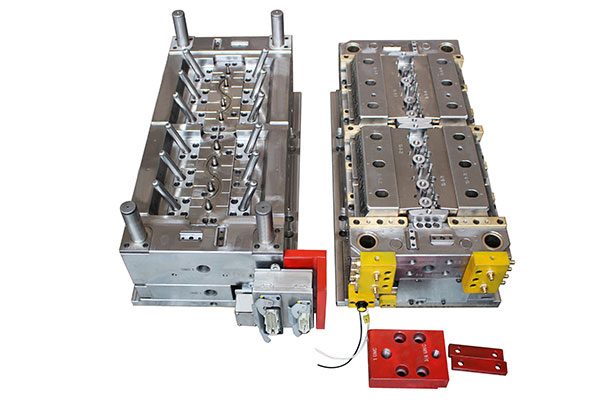

Small to medium mold series

These are plastic injection molds intended to produce small series, a few hundred to a few thousand parts. These molds are generally used over many years in order to make the investment profitable due to the large initial financial investment. These are often referred to as “family” molds that have several different cavities in the same mold.

Our solution: Unimold provides advice on creating a mold that can produce the desired number of parts, with the required length of service life. We adapt the choice of our steel and components as close as possible to your requirements. The type of injection is also designed to avoid overrunning the customer’s budget.

Large series molds

By appointment, these are plastic injection molds aimed at producing large series of several million parts. Cycle times, the ageing of the mold and its maintenance are all essential parameters to be considered. These are generally multi-cavity molds.

Our solution: In such cases we carefully choose the steel and component standards of the mold. For example, we use graphite columns, ball bearings on ejection guide pin, hardened steel and suitable surfaces treatments. Furthermore, during the realisation, all fitting controls and cycle times are crucial.

The various types of plastic

injection molds by their technical specificities

Overmolding mold

The principle of overmolding is to provide a molding around an element. This element is known as an insert. These inserts may be made of metal, plastic, or some other material. The latter is inserted into the mold before the injection, then the plastic is injected around it, which generally allows an extremely strong fixation between the two.

Our solution: We create many overmolding molds. For example, we overmold brass inserts with screw threads that allow screwing them in and metal items such as frames, screws and hand tools to name a few.

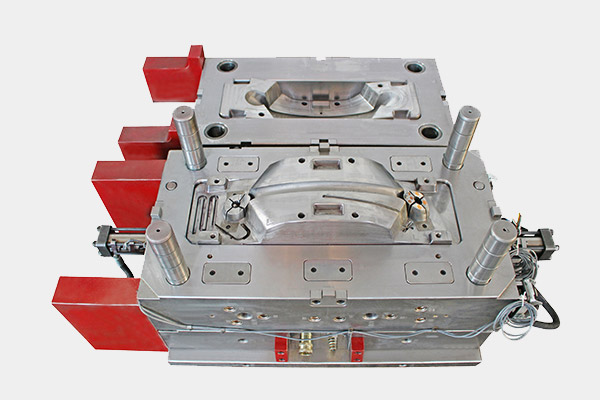

Gas-assisted plastic injection mold

The principle of this tool is to inject nitrogen gas into the molded part. The objective it to obtain material gains, improve cycle times and to enhance the part’s appearance. This is a complex process in which all the stages and injection settings must be optimised to obtain a proper result.

Our solution: We make this type of mold on a regular basis. Our test centre is fully equipped with a gas injection machine.

Bi-material plastic injection mold

Bi-material parts are made up of two materials. The purpose is generally to obtain a softer part or one of a different color. To produce this type of part, there are several methods: by transfer into the same mold or into two molds operating in “tandem press”; core-back process molding in the same tool; and rotating molds.

Our solutions: Unimold has already created numerous bi-material toolings by transfer in the same mold or by tandem press. We propose to perform trials at our test centre. We are also proficient in manufacturing bi-material molds with a core-back process.

Comments (2)

Hello,

I am inquiring if your company makes molds for golf equipment?

If you could please let me know that would be great.

Thank you,

Joshua Haywood

Hello Joshua,

Yes we can provid plastic inject tools for golf equipment. Please send us your enquiry with your specifications ( Cavity number, plastic raw material injected, type of injection gate, steel hardness, surface finishing,…)

Waiting for your information!

Unimold Team